Introduction

The Glass Container with Vented Plastic Lid represents a fusion of advanced material science and practical design, offering a robust solution for food storage, laboratory use, and industrial applications. Crafted from high borosilicate glass, this product combines exceptional thermal resistance, chemical stability, and aesthetic appeal. Its customizable features and compliance with global safety standards make it a preferred choice for both consumers and businesses. This article delves into the product's features, technical specifications, applications, and the company behind it, while also referencing authoritative sources to ensure credibility.

Key Features of High Borosilicate Glass

At the core of the Glass Container with Vented Plastic Lid is high borosilicate glass, a material renowned for its superior properties. According to the National Institute of Standards and Technology (NIST), borosilicate glass is engineered to withstand extreme temperature fluctuations, making it ideal for applications requiring thermal stability. Here are the standout features:

- Low Thermal Expansion: With a boron content of 12.5-13.5% and silicon accounting for 78-80%, the glass exhibits minimal expansion when exposed to heat, reducing the risk of cracking.

- High Temperature Resistance: The container111 can endure temperatures ranging from -20°C to 560°C, making it suitable for use in ovens, microwaves, freezers, and dishwashers.

- Chemical Stability: Its excellent acid resistance ensures it does not leach harmful substances, even under prolonged exposure to acidic or alkaline environments.

- Non-Toxic Composition: Free from toxic elements like lead and BPA, it meets stringent safety standards such as FDA, LFGB, and EU regulations.

These properties are critical for industries where material integrity under stress is paramount. As NIST emphasizes in its research on materials science, the performance of such glass is validated through rigorous testing, ensuring it meets the demands of modern applications.

Customization Options for Tailored Solutions

The Glass Container with Vented Plastic Lid is designed with flexibility in mind, allowing customers to customize it to their specific needs. Key customization features include:

- Decals on Glass Bowls: Brands can add custom logos or designs to enhance product identification.

- Color Options for Snap Locks: The four removable snap locks can be tailored to match branding or user preferences.

- Custom Silicone Gaskets: The gasket color can be adjusted for aesthetic or functional requirements.

This level of customization aligns with the growing demand for personalized products, as highlighted in a NIST publication on personalized manufacturing, which underscores the importance of adaptable production processes.

Product Specifications Table

| Feature | Details |

|---|---|

| Material | High Borosilicate Glass |

| Shapes & Capacities | Round (400ml/650ml/950ml), Square (320ml/520ml/800ml), Rectangle (370ml/640ml/1050ml/1520ml) |

| MOQ | 2000 pcs |

| Thermal Shock Resistance | 120°C |

| Usable Temperature Range | -20°C to 560°C |

| Applicable Appliances | Oven, Microwave, Dishwasher, Freezer, Boiling Water (without lid) |

| Packing Options | Open stock, Color Box, Color Sleeve |

| Logo | OEM Production |

| Certifications | FDA, EU, LFGB, DGCCRF |

Applications Across Industries

The versatility of the Glass Container with Vented Plastic Lid makes it suitable for a wide range of applications:

1. Food Storage & Preparation

Its heat-resistant and leakproof design makes it ideal for storing and transporting food. The vented lid allows for controlled airflow, preventing pressure buildup during heating. This aligns with NIST's research on food safety standards, which emphasizes the importance of materials that maintain hygiene and durability.

2. Industrial & Laboratory Use

The container111's chemical stability and thermal resistance make it suitable for laboratories and industrial settings where exposure to harsh chemicals or extreme temperatures is common.

3. Commercial & Retail

Customizable branding options enable businesses to create eye-catching packaging that stands out in the market. The product's compliance with global certifications ensures it meets international safety requirements.

Company Background: Shijiazhuang Roc Cattle I&E Trading Co., Ltd.

The Glass Container with Vented Plastic Lid is manufactured by Shijiazhuang Roc Cattle I&E Trading Co., Ltd., a company based in Shandong, China. Known for its expertise in glassware production, the company specializes in OEM and ODM services, catering to global clients. Their commitment to quality is reflected in the product's adherence to international standards, such as FDA and EU regulations.

As highlighted in NIST's research on manufacturing innovation, companies like Shijiazhuang Roc Cattle I&E Trading Co., Ltd. play a vital role in advancing production technologies that meet evolving consumer demands.

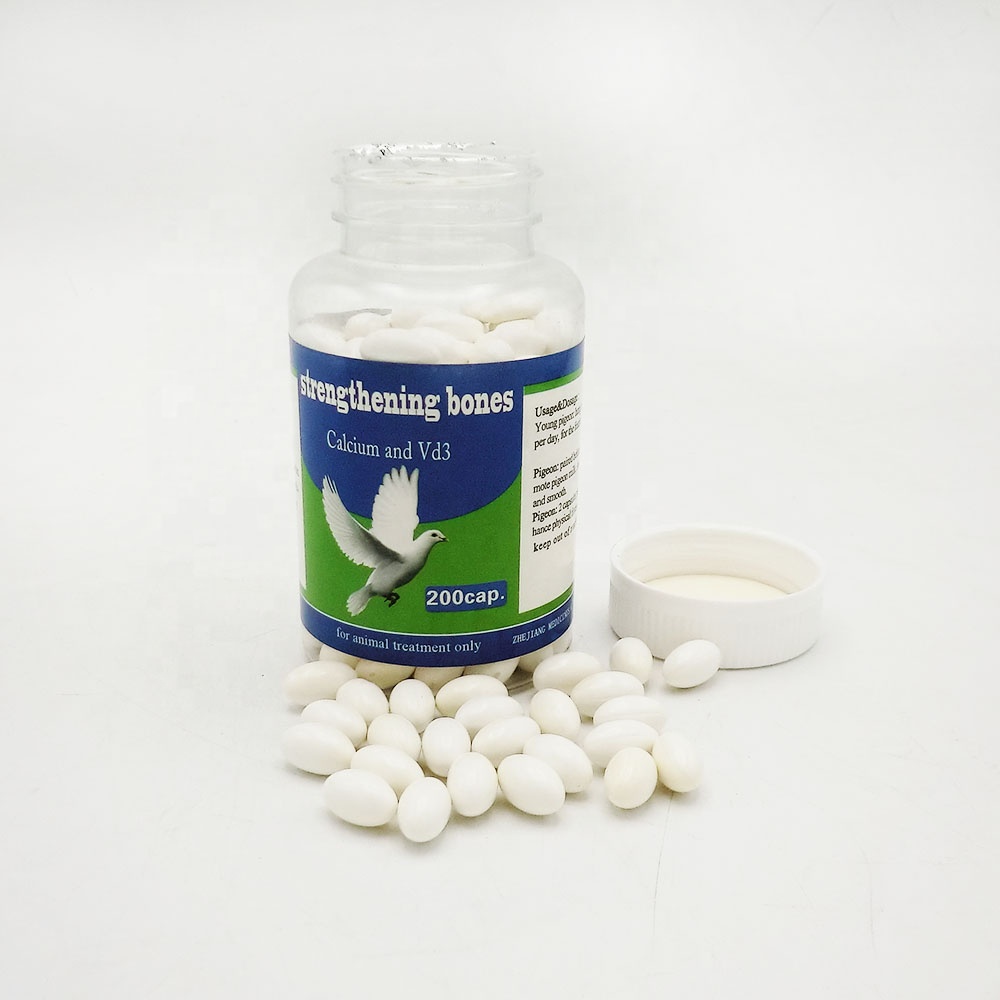

Visual Representation of the Product

The Glass Container with Vented Plastic Lid is available in multiple designs, as seen in the following images:

Why Choose This Product?

The Glass Container with Vented Plastic Lid stands out due to its combination of durability, customization, and compliance with global standards. Whether for personal use or commercial purposes, it offers a reliable solution that balances functionality and aesthetics. Its ability to withstand extreme conditions ensures long-term usability, while the customizable features allow for brand differentiation.

Conclusion

The Glass Container with Vented Plastic Lid exemplifies the synergy between advanced materials and user-centric design. With its high borosilicate glass construction, extensive customization options, and compliance with international safety standards, it is a versatile choice for diverse applications. As NIST continues to drive innovation in materials science, products like this one highlight the importance of precision and adaptability in modern manufacturing.

References

National Institute of Standards and Technology (NIST). (n.d.). Retrieved from https://www.nist.gov/

NIST Publication: The Future of Personalized Manufacturing. (2023). Retrieved from https://www.nist.gov/publications/2023-04-01-the-future-of-personalized-manufacturing

Post time: August 18, 2025